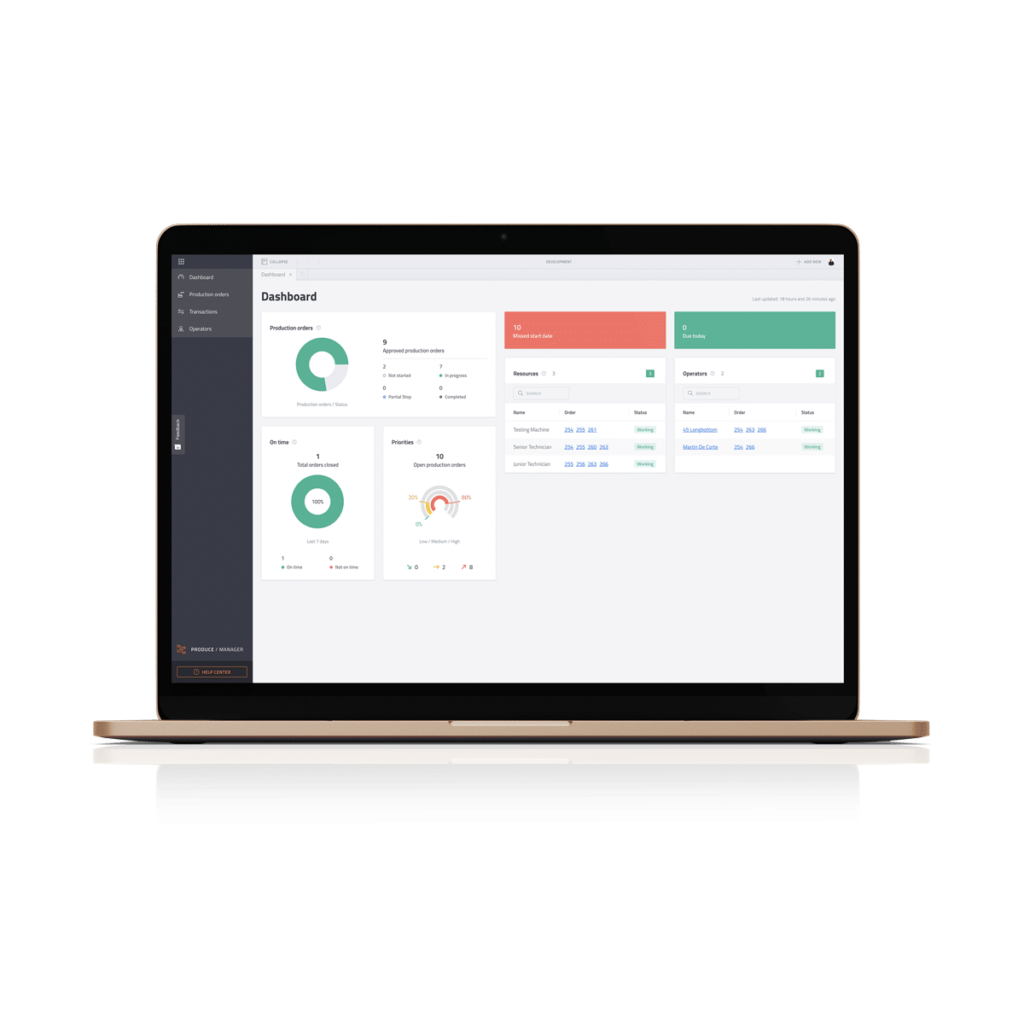

Benefit from a comprehensive production order backlog and progress view as well as from an automatic or manual priority assignment for an optimized production planning.

Manage production orders by planning, approving and tracking production steps in real-time. Get an instant and clear overview of your production process and increase the work performance on the shop floor.

Manual communication and adjustment processes between planning and production leads to inefficiencies in shop floor management.

Shop floor management is often not supported by ERP systems. The production backlog is communicated manually from planning to production.

Changes to production orders or altered priorities must be communicated manually and adjusted in a time-consuming process.

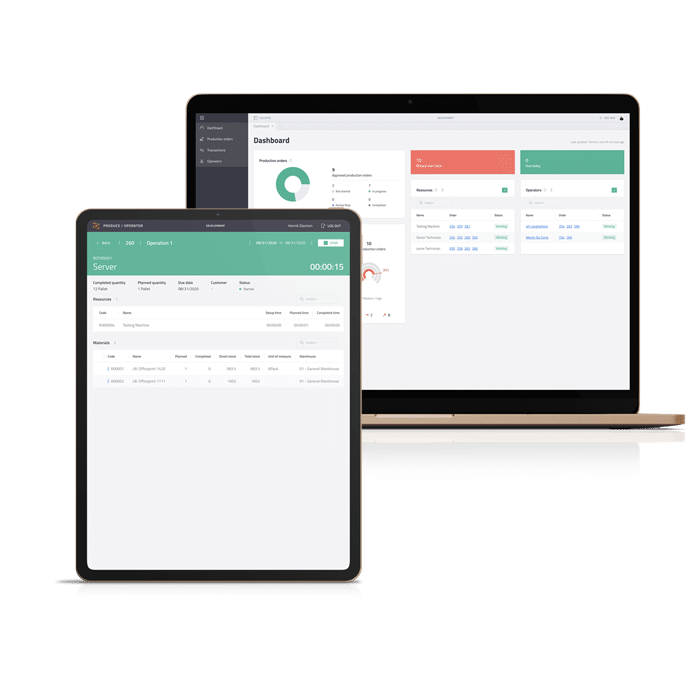

We offer you a comprehensive backlog management system that helps production managers to organize and prioritize production orders and support operators through paperless access in executing operations and collecting production data.

BEST PRACTICE WORKFLOW

Benefit from a comprehensive production order backlog and progress view as well as from an automatic or manual priority assignment for an optimized production planning.

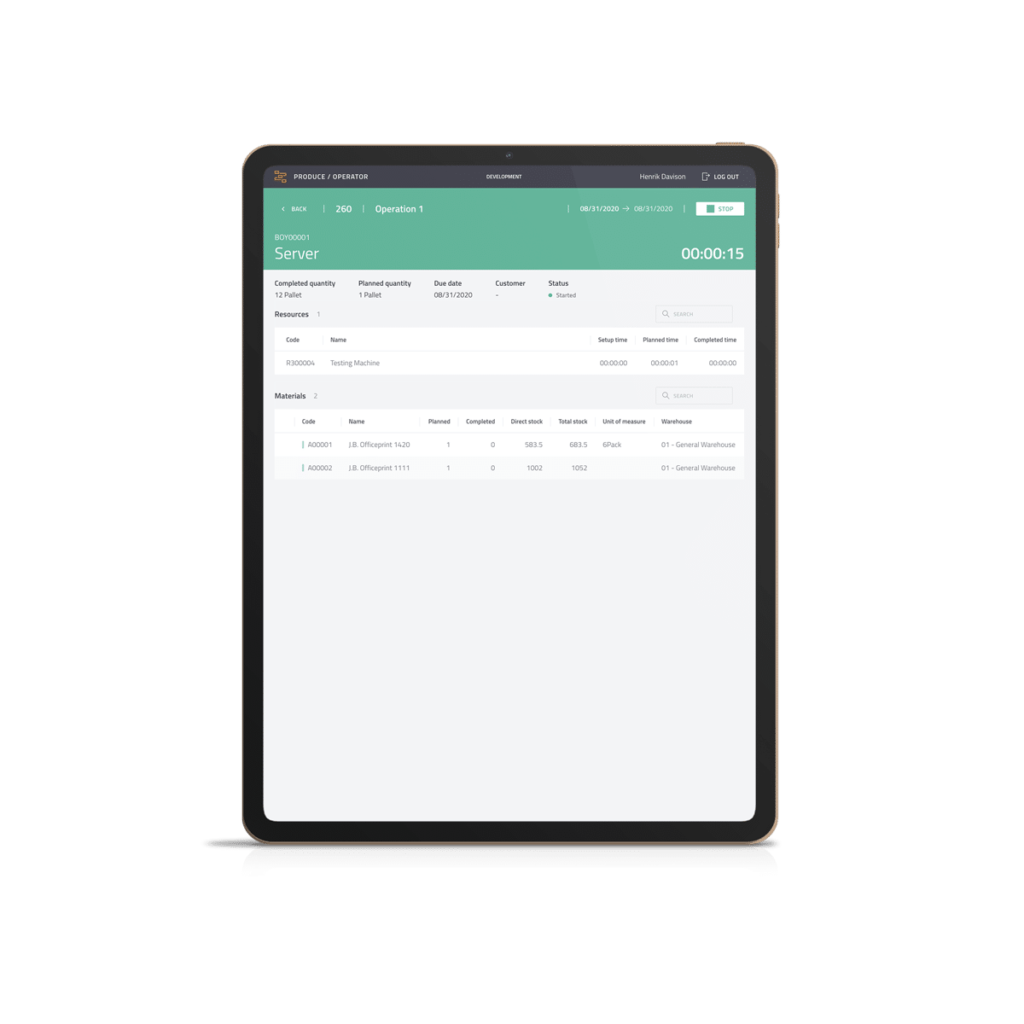

Enables you to quickly access material requirements and provides simple selection and release of the next production orders for shop floor employees.

Get a clear, paperless overview of the work. Select the next production order, view required materials and resources and production instructions, record time and materials usage, report finished production quantities and complete the processing.

Keep the overview through full visibility on real-time shop floor activities e.g which operator is working on what production order and resource.

Keep the overview

Prioritize your production orders to control the sequence and visibility on the shop floor terminal.

Paperless production

Access instructions, material and resource requirements and collect your production data paperless.

Real-time tracking

Monitor production progresses, check time and material costs, and complete the production order.

Request a demo and learn more about integrated processes and best practice workflows for a fast and fluid way of working.