Using a clear framework, each department is guided through the tasks that they're responsible for, ensuring that products are added to the system accurately and efficiently.

PRODUCT DEVELOPMENT

Plan what needs to be done for a new or changing product. Deliver complete and accurate information to production and achieve a smooth production process.

Requests for products are often handled manually outside the ERP solution, leading to no real-time overview, input errors and delays.

Adding products to the ERP is often seen as the greatest hurdle in the product development process; getting a product ready for production can be a complicated, manual task.

Communication between departments is essential to ensure the right materials and production methods are used. But this process is often managed manually, leading to mistakes and lost production time.

Netronic Manufacturing Solution removes this issue by providing a clear framework for each department, guiding them through each step in the process, and ensuring that products are added to the system efficiently and correctly.

BEST PRACTICE WORKFLOW

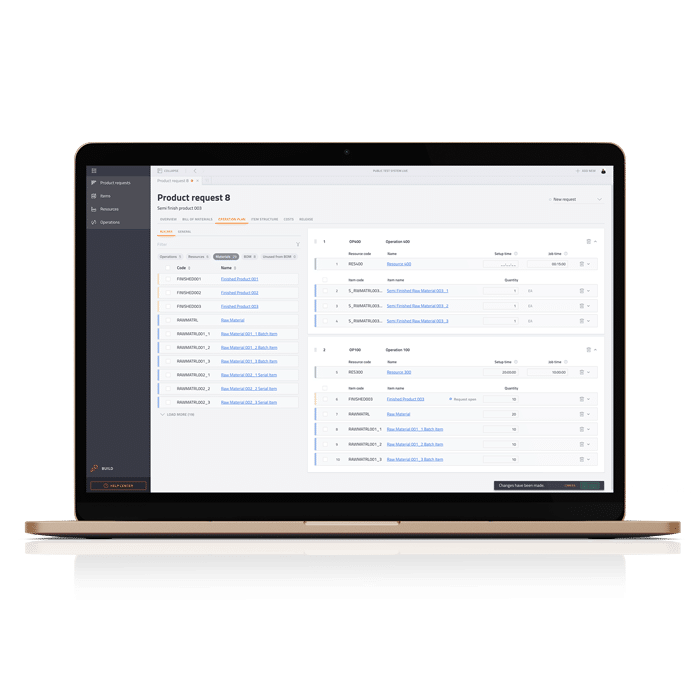

Using a clear framework, each department is guided through the tasks that they're responsible for, ensuring that products are added to the system accurately and efficiently.

Add or update new production items more quickly, including the management of the operation plan, ensuring that the right materials and production methods are used.

Determine material and labor costs based on the product structure, calculate manufacturing and sales costs and transfer the sales price to an ERP price list.

The integration of other stakeholders in the process, from sales or production, and access to real-time data allows product updates to be tracked and any issues to be resolved swiftly.

Planning board

Track and plan product development in real time, so you never lose track of what needs to be done.

BoM management

Mock-up operation plans using a fast, fluid interface before you send the item to the ERP.

Operation planning

Import, copy or build a Bill of Materials from pre-existing assets, or completely from scratch.

Request a demo and learn more about integrated processes and best practice workflows for a fast and fluid way of working.