Manage inspection plans with sample plans and quality targets for each inspection step. Build test steps with instructions for the inspector, and define quality targets and rules for how many samples should be taken.

Improve productivity and make better decisions in your quality department by automating inspection operations, optimizing data collection on the shop floor, and reacting to results in real time.

A lack of integrated quality control workflows makes it difficult for organisations to ensure consistently high product quality and secure customer loyalty.

As businesses expand and global supply chain infrastructure gets more advanced, there is more choice than ever in terms of who to buy from. Ensuring that your products maintain a consistently high quality is crucial in maintaining a strong relationship with your customers, and enables you to secure their repeat business in the future.

However, many ERP systems that control these supply chains do not have quality control as an integral part of their workflow, making it much harder for businesses to perform quality control checks and gauge their success.

We offer you a lean Quality Control process that enables quality managers to plan, automate and delegate work, and assists inspectors in running tests and recording results. You can manage inspection plans and define quality targets to ensure the excellence you wish to deliver to your customers.

BEST PRACTICE WORKFLOW

Manage inspection plans with sample plans and quality targets for each inspection step. Build test steps with instructions for the inspector, and define quality targets and rules for how many samples should be taken.

Process inspection plans and see what items need to be inspected, what tests you need to perform and their criteria for success while the system helps you to spot potential problems or failed tests along the way.

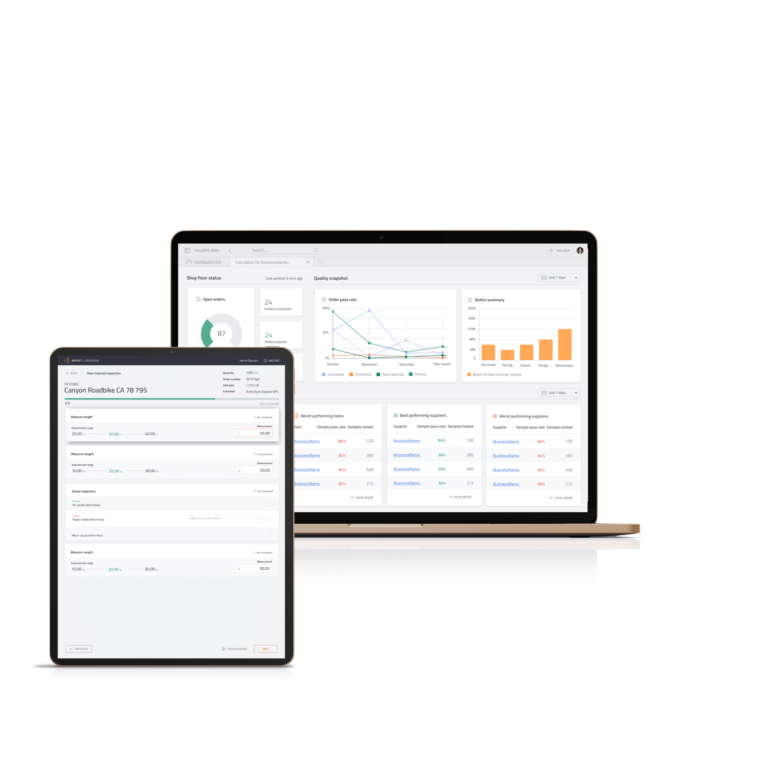

Monitor the execution of inspection orders and quality trends. See results in real time and make quick decisions relating to subsequent tasks.

Deep dive into test results and track global quality trends. Detailed view of results per inspection order and cumulative view of the current quality status via the quality dashboard.

Enhanced customer loyalty

Maintain customer confidence by ensuring the quality of the purchased materials for production, the correct processing of the production steps up to the finished product.

Terminal access

Get a clear, paperless overview of the work by using shop floor data collection for processing inspection steps and completing inspection orders.

Reduced production costs

Achieve the best balance between quality and costs with flawless production processes without delays due to poor-quality raw materials.

Request a demo and learn more about integrated processes and best practice workflows for a fast and fluid way of working.